-

Prevention of Weighbridge frauds

Prevention of Weighbridge frauds

Weighbridge

A weighbridge has a platform mounted on a concrete foundation for weighing a vehicle. At the bottom work - beneath the platform - levers (mechanical)/load cells (electronic) are used for sensing the load placed. By weighing the vehicle both loaded (Gross weight) and empty (Tare weight), the load carried by the vehicle (Net weight) can be found.

In mechanical weighbridge, the load receptor (platform) will be fully supported on an arrangement of levers. The display will be steel yard type/analogue Dial type.

In electronic weighbridge, the load receptor (platform) will be fully supported on load cells. A load cell is a transducer, which converts gravitational force to electrical signals. This analog signal will be converted to digital and be displayed digitally.

The different types of weighbridges are mechanical (Dial type), electronic (pit type), rail weighbridge, portable weighbridge (one scale unit for each wheel of the vehicle) etc.

The capacity (Max.) of the weighbridge can be 10, 30, 40, 50, 60, 100, 120, 150 ton

Uses

Weighbridges are used by industries for the bulk movement/selling of goods, such as mines/quarries.

To check whether a vehicle is loaded beyond its permitted load capacity.

To levy tax based on the weight of the commodity at inter state check posts.

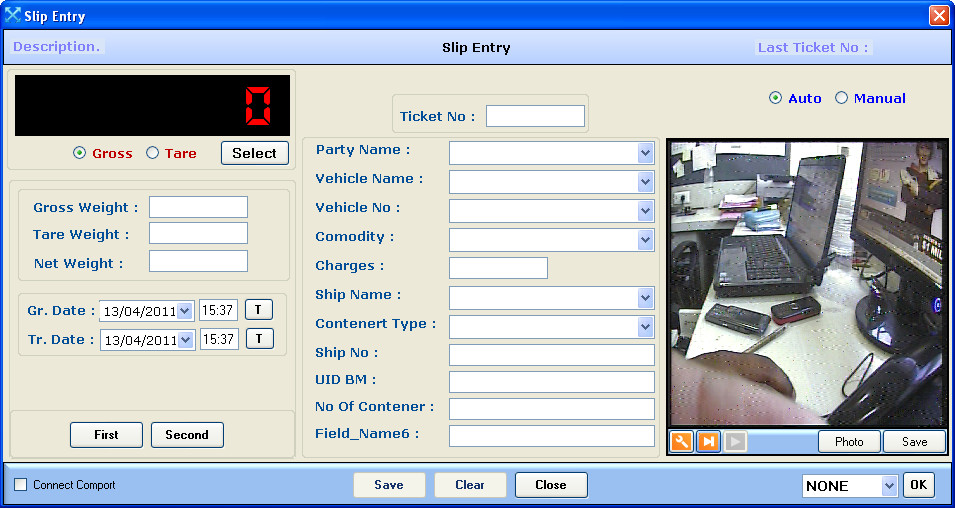

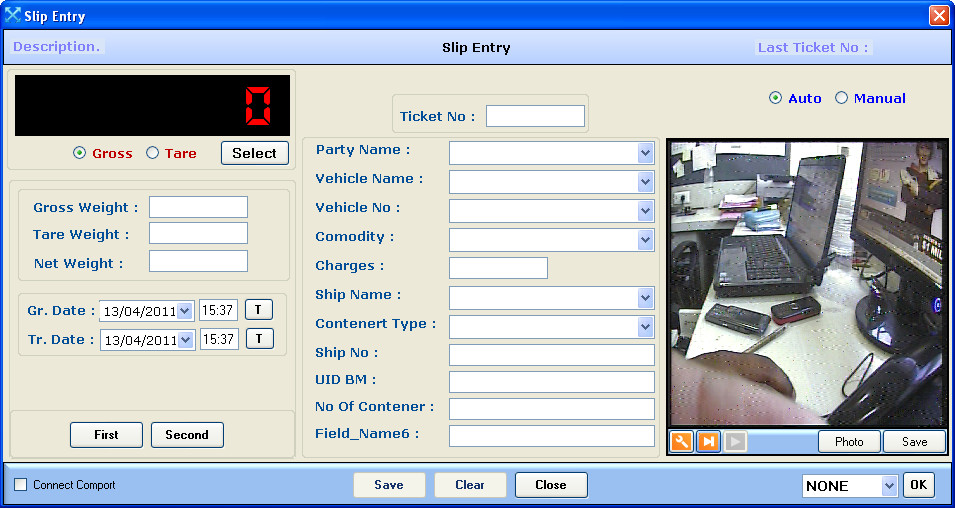

When goods are transported/delivered, it should accompany with a invoice/delivery note/weighbridge ticket. A weighing ticket

should contain

1. Date & Time of weighing

2. Vehicle No.

3. Nature of load

4 Gross weight, Tare weight, Net weight

Tags for this Thread

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote

Bookmarks